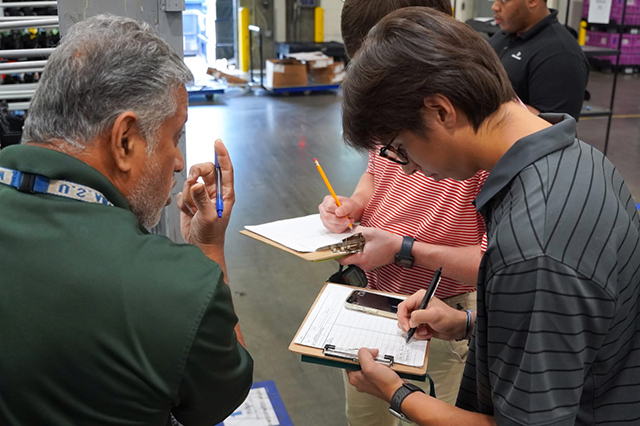

Photos provided by Dräxlmaier

Freshman Corbin White was considering the architecture program at Clemson University when he learned about a new major that had just been added at USC Upstate.

Industrial engineering, which welcomed its first cohort of 32 students this fall, was created to address an industry shortfall in the Upstate. The 10-county region is expected to need more than 1,000 new industrial engineers over the next five years to meet demand in the manufacturing sector, according to a report by USC Upstate’s Center for Business Analytics and Community Research.

The new major is designed to get students workforce ready well before they graduate. As part of their coursework, students participate in Lab in Industry, a unique class that takes them to 10 different companies for hands-on experiences throughout the semester.

“We are not trying to produce engineers who are theoretical,” says Don Bent, executive in residence and professor of practice, who collaborated with regional manufacturers to set up Lab in Industry. “These are engineers who will go into real manufacturing environments and gain real experience, but also then lead the future of manufacturing advancement.”

That practical knowledge and experience appealed to White. “It’ll get me into the workforce early, it’ll let me keep working with my hands so I don’t have to sit behind a desk, and it’ll get me connections with all the local companies,” he says.

Gimantha Perera, who will be teaching the new industrial engineering classes, is excited about building a program from the ground up. His teaching method builds on the strengths and experiences that his students bring to the classroom.

If, for example, he’s doing a lesson on supply chain, he might ask his students to take what they’ve been discussing theoretically and describe its application to a supply chain they’re familiar with, perhaps from a family business or a job they’ve held.

Lab in Industry is yet another way to help students make those connections between what they’re learning and what they’ve observed and experienced firsthand.

“There’s a road that has already been built in their minds to this information that’s stored, they’re just taking that road and then adding a little bit more on it,” Perera explains.

Another important component of the major is developing the soft skills that are critical in the field. Because industrial engineers design, install, maintain and improve manufacturing processes, their job requires strong communication and critical thinking skills.

“Industrial engineering is very people focused,” Bent says. “It’s not just about equipment. It’s about making people more efficient and interacting with people.”

Perera agrees. He tells his students that frontline workers often think their jobs are about to be eliminated when they see an industrial engineer show up.

But in reality, “I prefer to see us as people who eliminate tasks and not people,” he says. “It’s not about telling someone, oh, you need to leave now. It’s more about saying, I think we’re underutilizing you as a person, because you as a person have the capacity to contribute way more to this company.”

Industrial engineers themselves will likely face some career impacts from companies’ increased use of artificial intelligence. But becoming familiar with AI will be part of students’ training as well.

“Artificial intelligence is key in many engineering disciplines,” says Jeannie Chapman, dean of the College of Science and Technology. “So we already built an ‘artificial intelligence in engineering’ course into our curriculum.”

At this stage in their education, Perera wants his students to learn how AI thinks and works and where it can go wrong. “Because that’s where you’re going to add value – shoring up those weaknesses that the AI model has.” He anticipates having students use AI on projects, too, such as for generating data sets for simulations.

Industry response to the new program has been extremely positive, Bent says. So many companies offered to be part of Lab in Industry that it may become a part of other classes in the program as well.

During the first week of classes, students visited Dräxlmaier and took part in a time study with company engineers. With nine more site visits to go, students will be exposed to a wide variety of jobs and manufacturing environments, gaining insights to help shape their career decisions, Perera notes.

“It’s a great window into what they could be,” he says.